Blow Off/Bypass/Diverter Valve Discussion

- on April 06, 2020

- Categories: Tech Articles

What is a BOV/BPV/Diverter valve, which one do I have, and what does it do?

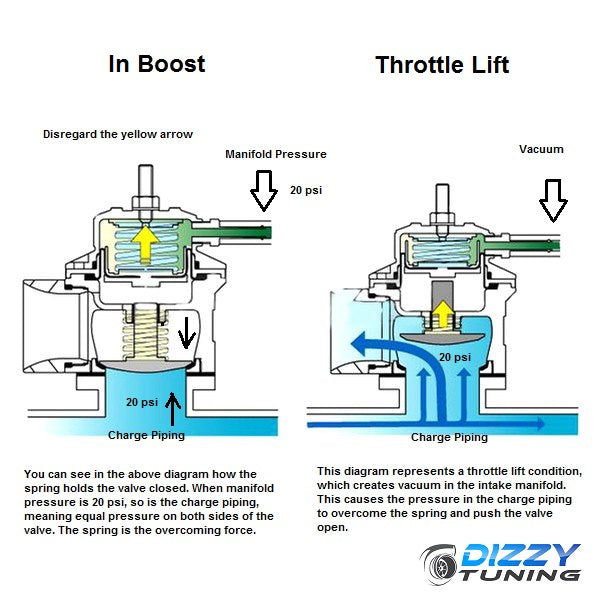

These are all valves (or gates, if you read my wastegate explanation), that are located on the charge side piping of a turbocharged vehicle. They are typically located directly before the throttle body, and their purpose is to relieve boost pressure, after a throttle lift condition. This pressure can be as high as 20-30 psi on some vehicles. Imagine when you let off the accelerator, all your boost pressure crams against the throttle plate and has nowhere else to go but back into the compressor housing of the turbo. This usually causes a terrible surge or flutter sound. The valve is designed to open in these instances, and relieve the boost pressure, preventing throttle plate and/or turbocharger damage.

A BOV (or Blow Off Valve) will vent this boost pressure to the atmosphere (or VTA for vent to atmosphere). This typically results in much louder releases of air, which seems to be much more desirable to some. The drawback to a VTA valve on a MAF based vehicle (like the Mazdaspeed), is that you will be losing metered air when the valve opens (since it is located AFTER the MAF sensor), resulting in rich AFR’s during shifts and occasional backfires. VTA valves do not have the same effect on Speed Density based vehicles (like the EcoBoost), as these ECU’s make their airflow calculations based off a combination of manifold pressure, barometric pressure, temperature, etc. So losing air from a VTA valve will not have the same effect on these engines.

A BPV (or ByPass Valve) uses the same principle as the VTA valve, but only it recirculates the relieved pressure back into the intake system. The reasoning for this is that no metered air is lost into the atmosphere. Everything that the MAF sensor read is either going into the combustion chamber, or is being redirected back into the intake, and will soon be making it to the combustion chamber. The result is consist stoichiometric AFR’s during all operating conditions, including throttle lift. Pretty neat!

A Diverter Valve is basically the same as a Bypass Valve, but this term is more commonly used in the Audi/VW world. Diverter valves are also usually located directly on the compressor housing of the turbocharger (like the EcoBoost), as opposed to before the throttle body (like the Mazdaspeed). This allows for less plumbing and hoses (parts), and less chance of leaks or failure (service), so it’s win/win for the manufacturer.

All of the above valves may be offered in either a mechanical or electromechanical type. The mechanical valve consists of a chamber, with a pressure source connected to it (typically the intake manifold). Within this chamber, there is also a spring loaded valve closing off the charge piping to the atmosphere (or intake tract). Please see the photo I have attached to this post, for more information on the function of the mechanical valve. The electromechanical type is operated by a 12v solenoid, that can open and close the valve with outputs from the ECU. These outputs can be monitored on the EcoBoost ECU using the monitor named “BPV Mode”. This monitor will indicate a “0” when the valve is closed, and a “1” when the valve is open.

Stay tuned for another video giving more detail and visualization of how the valve functions on the EcoBoost turbochargers!

These are all valves (or gates, if you read my wastegate explanation), that are located on the charge side piping of a turbocharged vehicle. They are typically located directly before the throttle body, and their purpose is to relieve boost pressure, after a throttle lift condition. This pressure can be as high as 20-30 psi on some vehicles. Imagine when you let off the accelerator, all your boost pressure crams against the throttle plate and has nowhere else to go but back into the compressor housing of the turbo. This usually causes a terrible surge or flutter sound. The valve is designed to open in these instances, and relieve the boost pressure, preventing throttle plate and/or turbocharger damage.

A BOV (or Blow Off Valve) will vent this boost pressure to the atmosphere (or VTA for vent to atmosphere). This typically results in much louder releases of air, which seems to be much more desirable to some. The drawback to a VTA valve on a MAF based vehicle (like the Mazdaspeed), is that you will be losing metered air when the valve opens (since it is located AFTER the MAF sensor), resulting in rich AFR’s during shifts and occasional backfires. VTA valves do not have the same effect on Speed Density based vehicles (like the EcoBoost), as these ECU’s make their airflow calculations based off a combination of manifold pressure, barometric pressure, temperature, etc. So losing air from a VTA valve will not have the same effect on these engines.

A BPV (or ByPass Valve) uses the same principle as the VTA valve, but only it recirculates the relieved pressure back into the intake system. The reasoning for this is that no metered air is lost into the atmosphere. Everything that the MAF sensor read is either going into the combustion chamber, or is being redirected back into the intake, and will soon be making it to the combustion chamber. The result is consist stoichiometric AFR’s during all operating conditions, including throttle lift. Pretty neat!

A Diverter Valve is basically the same as a Bypass Valve, but this term is more commonly used in the Audi/VW world. Diverter valves are also usually located directly on the compressor housing of the turbocharger (like the EcoBoost), as opposed to before the throttle body (like the Mazdaspeed). This allows for less plumbing and hoses (parts), and less chance of leaks or failure (service), so it’s win/win for the manufacturer.

All of the above valves may be offered in either a mechanical or electromechanical type. The mechanical valve consists of a chamber, with a pressure source connected to it (typically the intake manifold). Within this chamber, there is also a spring loaded valve closing off the charge piping to the atmosphere (or intake tract). Please see the photo I have attached to this post, for more information on the function of the mechanical valve. The electromechanical type is operated by a 12v solenoid, that can open and close the valve with outputs from the ECU. These outputs can be monitored on the EcoBoost ECU using the monitor named “BPV Mode”. This monitor will indicate a “0” when the valve is closed, and a “1” when the valve is open.

Stay tuned for another video giving more detail and visualization of how the valve functions on the EcoBoost turbochargers!